Investing in the Manufacturing

Workforce of the Future

Overview

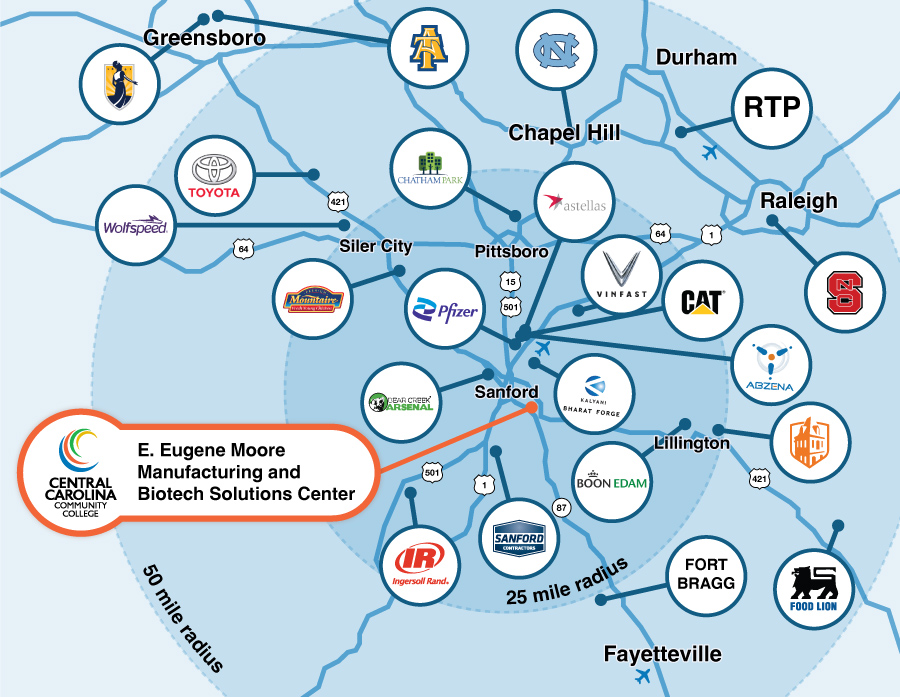

The E. Eugene Moore Manufacturing and Biotech Solutions Center located at Central Carolina Community College's (CCCC) Lee Main Campus sits in the middle of a region experiencing an explosion of economic development. Within one hour of the center, there are 104,000 existing manufacturing jobs with 20,000+ more announced in the past 18 months—including 7,500 with VinFast and 1,800 with Wolfspeed, both within CCCC's service area. This development is already causing a ripple effect, attracting support industries, such as FedEx, to the area. The Center was made possible by Lee County’s purchase of a 22-acre former manufacturing facility. Funding from a private donation, coupled with pending grant applications, will provide the project’s initial investment.

When renovation is complete, the now vacant facility will be transformed to a one-of-a-kind, world-class education center—the largest facility in the state focused on addressing the workforce needs of advanced manufacturing and biotechnology. The Moore Center’s 220,000 square feet of training space also boasts access to nearby 4-lane limited-access highways leading to industries throughout the region.

The Moore Center is poised to successfully address the workforce needs of North Carolina’s current and future employers by focusing on three core goals:

- Recruiting the manufacturing workforce’s next generation of skilled workers;

- Training in state-of-the-art manufacturing technologies to support current and future manufacturing and biotechnology environments; and

- Providing North Carolina with a world class resource capable of driving future economic development by supporting and attracting the businesses of tomorrow.

The Moore Center will not only meet existing and critical regional workforce needs but also fuel regional economic development by showcasing North Carolina's ability to attract, train, and retain a high-quality workforce.

What they’re doing with this investment and this facility is the single greatest opportunity for economic development and attracting more investment here.

Senator Thom Tillis U.S. Senator for North Carolina

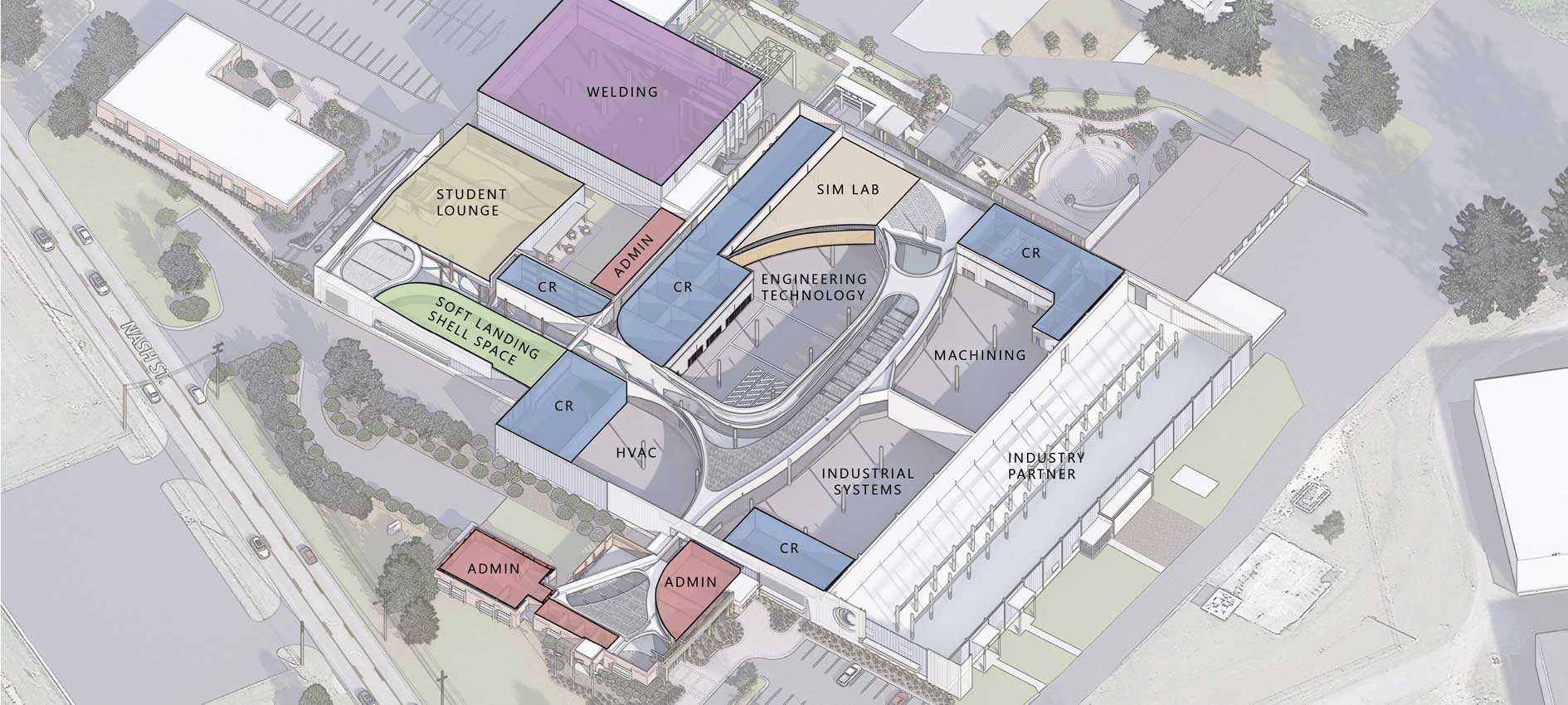

Facility*

The Moore Center's 22-acre campus will include state-of-the-art facilities for training in biotechnology, computer integrated machining, industrial automation, welding, robotics, 3D Printing/Additive Manufacturing and short-term, on-demand customized skills training. There will also be soft landing spaces for new and expanding industries undergoing facility construction.

The Moore Center will build on the community college tradition of creating unique programs designed to quickly address rapidly evolving industry workforce needs. Specific training focus areas will include:

*proposed layout

- CDL - A 2,700 square foot building hosting CCCC’s CDL commercial truck driver training program with classroom spaces, offices and a driving range for behind-the-wheel instruction.

- Biotechnology Training Center - A 9,908 square foot building with two BioWork laboratories, a general use laboratory, lab preparation space, a clean room, two equipment laboratories, lab storage, and four offices.

- Showcase Robotics/Industry 4.0 - A flexible demonstration area, designed to highlight the latest advances in manufacturing technology, local career paths, and ongoing projects of interest.

- Soft Landing Space - An incubator space, designed to allow entrepreneurs to nurture and develop their ideas until they are ready to move into their own space.

- Engineering Technologies and Industrial Systems - Areas for training in automation, solid-state fundamentals, digital concepts, microprocessors and industrial systems including PLCs (programmable logic controllers), hydraulics, pneumatics, industrial electricity, electrical systems, motors, control systems, rapid prototyping, etc.

- Industry 4.0/NCMEP - Operated in partnership with N.C. State University’s Manufacturing Extension Partnership (MEP) for North Carolina, this space will provide collaborative learning spaces for community college students in either Engineering or Industrial Technologies to work in conjunction with engineering students from universities on project-based learning experiences involving real-world industry processes and problem solving. This space will also be used by NC MEP to assist industries with next generation solutions.

- Computer Integrated Machining - Area for training in basic and advanced machining operations, computer aided drafting, computer aided machining, computerized numerical control equipment and high speed multi-axis machining.

- Welding - Separated from the other training areas to accommodate safety shielding, the Welding area will provide space for training in MIG, TIG, stick, plasma arc, Oxyfuel, carbon arc and robotic welding, and will include a flex space for short-term, on-demand customized welding training.

- VinFast - A 30,000 sq ft. dedicated to supporting VinFast’s future manufacturing facility in nearby Triangle Innovation Point.

- The Warehouse - Home of short-term, on-demand customized skills training, The Warehouse will include a General Motors SWE (Simulated Work Environment) providing hands-on training for Continuous Improvement (Lean, Six Sigma), cross-functional collaboration and leading effective teams.

Economic Development

A world-class resource capable of driving future economic development

When complete, the E. Eugene Moore Manufacturing and Biotech Solutions Center will be a one-of-a-kind, world-class education center—the largest facility in the state focused on addressing the workforce needs of advanced manufacturing and biotechnology. Not only will it facilitate the training of the manufacturing sector’s next generation of workforce, it will also serve as a key resource in attracting new industries to the region, and the state of North Carolina.

- Largest facility in the state, capable of supporting the largest economic development projects, such as the future VinFast facility in Chatham County

- Easy access via nearby limited-access, 4-lane highways and short drives to Raleigh Executive Jetport (15 minutes) and Raleigh Durham International Airport (45 minutes)

- Soft Landing is an area for new manufacturing businesses in the area to begin establishing operations while their new site is under development. It is designed to provide office space as well as access to regional support resources as companies arrive and begin establishing themselves in the area.

- State of the art training equipment to meet the evolving needs of advanced manufacturing, including biotechnology, computer integrated machining, industrial automation, robotics, 3D printing/additive manufacturing,

- Incubator and collaborative Industry 4.0 space will be available for entrepreneurs to partner with the community college and universities

- Workforce recruiting center, highlighting local career pathways and the technology utilized by local advanced manufacturers

- Resources available via CCCC’s partnerships with the National Science Foundation, the National Institute for Innovation in Manufacturing Biopharmaceuticals (NIIMBL), N.C. State University’s Manufacturing Extension Partnership (MEP) for North Carolina, the U.S. Department of Education, the U.S. Department of Labor, and the North Carolina Community College System.

- Access to CCCC’s extensive network of student support programs, available to new and incumbent workers participating in short-term and curriculum programs at the college

While other states have created similar centers to meet this challenge—such as the Center for Manufacturing Innovation in South Carolina and the Robert C. Byrd Institute in West Virginia—none of them match the Moore Center in size, or in regional new job growth.

CCCC’s E. Eugene Moore Manufacturing and Biotech Solutions Center will support and enhance SAGA's economic development efforts while fostering collaborative partnerships between employers and the educational institutions charged with developing and sustaining a robust local talent pipeline.

Jimmy Randolph CEO Sanford Area Growth Alliance (SAGA)

Skilled Workers

Within an hour of Sanford, North Carolina, there are 104,000 existing biotechnology and advanced manufacturing jobs with 20,000+ more announced in the past 18 months, including:

| Job Announcements | Company | Sector | Location |

|---|---|---|---|

| 7,500 | VinFast | Automotive | Moncure |

| 3,000 | Apple | Technology | RTP |

| 2,100 | Toyota | Automotive | Greensboro |

| 1,800 | Wolfspeed | Semiconductors | Siler City |

| 1,750 | Boom Supersonic | Aviation | Greensboro |

| 1,500 | Fidelity | Investment | RTP |

| 725 | Fujifilm | Pharmaceutical | Holly Springs |

| 355 | Amgen | Biotechnology | Holly Springs |

| 250 | Power Technology Company | Power | Durham/RTP |

| 250 | Science 37 | Clinical Trials | Morrisville |

| 235 | Service Offsite Solutions (SOS) | Construction/Homebuilding | Sanford |

| 220 | Technimark, LLC | Healthcare Manufacturing | Asheboro |

| 200 | Catalent | Biotech | Durham |

| 200 | Jaguar Gene Therapy | Gene Therapy | Durham |

| 145 | Fujifilm | Pharmaceutical | Morrisville |

| 135 | Alamance Foods, Inc. | Food Processing | Burlington |

| 129 | Sumitomo Forestry America, Inc. | Housing & Wood Products | Archdale |

| 78 | Cambrex | Pharmaceutical | High Point |

The Moore Center is focused on remedying the mismatch between the manufacturing skills of the past, and the 21st century skills needed for the advanced manufacturing environments of today and tomorrow.

Central Carolina Community College is on the front line of training candidates for these opportunities, while simultaneously building the pipeline of workers for the future. From introducing an elementary student to the wonders of robotics, to providing an adult learner with skills in 3D printing, the Moore Center will be a place to engage, prepare, and train the region’s existing and future workforce.

Engaging Youth in Manufacturing Careers - Many regional youth are unaware of advanced manufacturing careers or see them as manufacturing jobs of the past—line work with aging machines in dark warehouses. Today’s employers in this sector use advanced technology in modern facilities, and the Moore Center will demonstrate this to students and teachers alike through tours, showcase areas, camps and other immersive experiences. CCCC’s partnership with local high schools and the North Carolina Career and College Promise program will provide high school students the opportunity to take classes, for free, in this world-class educational center, increasing their likelihood of pursuing a career in advanced manufacturing.

Recruiting Adult Learners - Like youth, many adults are unfamiliar with the high-wage, highly skilled jobs available in their own backyard. Training at the Moore Center will take citizens from low-paying, low-skilled positions to well-paying and upwardly mobile careers. Partnerships with local workforce development boards, NC Job Centers, and community non-profits will help attract adults looking to change their career path. CCCC’s own College and Career Readiness programs, as well as Department of Labor Funded YouthBuild program will serve as additional sources to recruit adults and young adults. Work-based learning, internship, and apprenticeship opportunities will ensure all learners receive the hands-on training needed to ensure a good fit between worker, career pathway, and employer.

Incumbent Worker Training - A September 2020 survey of regional biopharma industries indicated their top priority was training opportunities for career advancement of current employees. Through its Customized Industry Training programs, CCCC will continue to meet the training needs of current sectors' workers in The Warehouse - a separate building home to the General Motors SWE (Simulated Work Environment) providing hands-on training for Continuous Improvement (Lean, Six Sigma), cross-functional collaboration, and leading effective teams. Training here can be adapted to the specific needs of any organization and can include topics such as work environment, quality control, technical skills, safety, and leadership.

The Moore Center’s modern and engaging architecture, state-of-the-art technology and equipment, and collaborative spaces will showcase pathways to advanced manufacturing careers for youth, adults, and incumbent workers alike.

This educational facility will be a key source of workforce talent for current and potential future employers in Lee County, producing graduates with the specific skills and experience needed for success in advanced manufacturing industries.

Jennifer C. Karatka Senior Manager, QA Document Control & Training Astellas Gene Therapies

Timeline

-

Fall 2021

Lee County purchases legacy Magneti Marelli facility for CCCC

-

December 2021

Magneti Marelli exits the facility

-

December 17, 2021

New facility named in recognition of E. Eugene Moore's $2 million investment

-

January - June 2022

Lee County assess and cleans site; CCCC begins site planning process

-

July 2022

Lee County leases site to CCCC

-

August 2022

CCCC begins facility development of the CDL and Biotechnology buildings

-

Spring 2023

CDL classes to begin at Moore Center

-

Summer 2023

Begin design of Phase 1 for Manufacturing building

-

Fall 2024

Biotechnology classes to begin at Moore Center

-

Fall 2024

Phase 1 Manufacturing classes to begin at Moore Center

We feel that the E. Eugene Moore Manufacturing and Biotech Solutions Center will be an exceptional driver of economic growth in Lee County and our service area for years to come. We are grateful for Mr. Moore's generous donation that will help students' educational and career dreams become realities.

H. Julian Philpott Jr. Chairman CCCC Board of Trustees

Contact

For more information contact